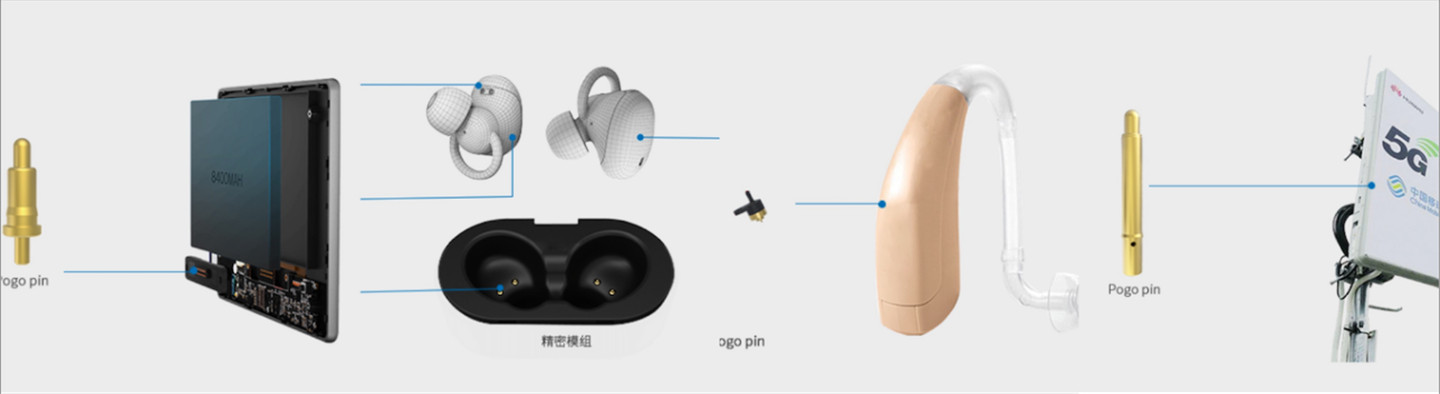

Products

Bending Spring Loaded Contact Pogo Pins

Specification

|

Material |

Plunger/barrel: Brass Spring: Stainless steel |

|

Electroplating |

Plunger: 5 micro-inch minimum Au over 30-80 micro-inch nickel |

|

Electrical specification |

Contact electrical resistor: 50 mOhm Max. Rated voltage: 5V DC Max Rated current: 1.5A |

|

Mechanical performance |

Life: 10,000 cycle min. |

Rongqiangbin

Our company’s spirit of "customer first, integrity first" principle, has a strong POGO PIN industry technology production team, and a number of enterprises to establish a long-term cooperative relationship. Our company has obtained ISO9001:2015 version of the international authoritative quality management system certification, has a strong quality management team and environmental management system, to provide customers with all kinds of high quality and environmental protection requirements of the products.

The main customers are Honeywell, Samsung, SIEMENS AG, ZTE, 360, QCY, HAYLOU, Shanghai Laimu, Luxshare Group, Aoni Electronics, Ampheno Group and other well-known enterprises.

FAQs

Pogo pins are quality tested using a variety of methods, including visual inspection, electrical testing, and environmental testing.

Contact resistance is the resistance between the two mating surfaces of a connector. This is important because it affects the performance of the electrical connection.

Contact resistance can be reduced by using high-quality materials, optimizing connector design, and keeping connectors in good condition.

Environmental factors that can affect pogo pin performance include temperature, humidity, dust, and vibration.

There are several ways to clean the pogo pins, including wiping with a dry cloth, using a mild cleaning solution, or using compressed air.