Products

DIP Spring Loaded Pogo Pin Socket

Specification

Remark: Considering the difference between test spot and actual work spot, the impedance test condition defined by Top-Link is based on the whole working stroke. This is what we generally said dynamic impedance testing, it differs from the static test condition of ELA-364923, the durability test standard is also based on this test condition.

Rongqiangbin is equipped with comprehensive inspection and reliability testing equipment.

Rongqiangbin attaches great importance to quality management of each link, including IQC, IPQC, 100% dynamic testing of spring force and contact impedance , 100% appearance inspection, FQC sampling inspection, CQC, design verification, regular reliability testing, failure analysis, and so on.

Rongqiangbin has implemented strict and effective quality control over each link which includes product design, sample preparation, trial production and mass production. As a consequence, our product quality is guaranteed.

|

Material |

Plunger/barrel: Brass Spring: Stainless steel |

|

Electroplating |

Plunger: 3 micro-inch minimum Au over 50-120 micro-inch nickel Barrel: 3 micro-inch minimum Au over 50-120 micro-inch nickel |

|

Electrical specification |

Contact electrical resistor: 100 mOhm Max. Rated voltage: 12V DC Max Rated current: 1.0A |

|

Mechanical performance |

Life: 10,000 cycle min. |

Pogo pin connector OEM type

1, Small diameter, fine type products: The minimum can be done is below 0.75

2, High durability: Maximum durability of up to 1 million times

3, Large current: Maximum up to 15A current

4, High reliability: 100% dynamic impedance testing to ensure 100% functional zero defects

5, Lower operating height: Minimum working height of up to 1.5mm, the chopping block can be lower

6, High precision (size & forward force): Height tolerances up to +, – 0.05mm positive up to + / – 10%

7, Non-standard structure: Customer requirements can be customized according to customer requirements, such as: mushroom head structure

Application:

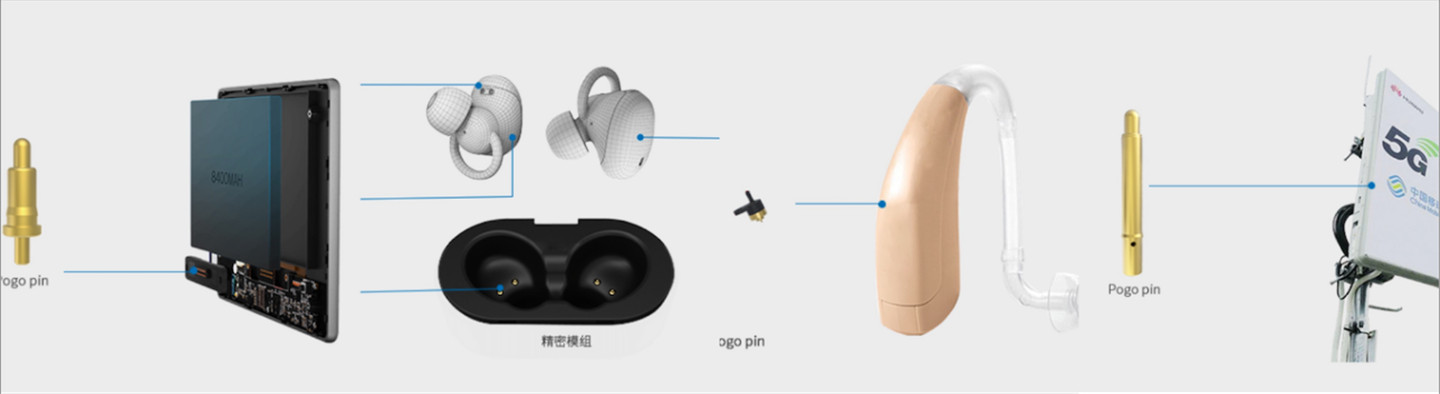

Intelligent wearable devices: Smart watches, smart wristbands, locator devices, Bluetooth headphones, smart wristbands, smart shoes, smart glasses, smart backpacks, etc.

Smart home, smart appliances, air purifiers, automatic controllers, etc.

Medical equipment, wireless charging equipment, data communication equipment, telecommunications equipment, automation and industrial equipment, etc;

3C consumer electronics, laptops, tablets, PDAs, handheld data terminals, etc.

Aviation, aerospace, military communication, military electronics, automobiles, vehicle navigation, testing fixtures, testing equipment, etc

FAQs

RQB: Yes, we are the experienced manufacturer in this industry, which can provide OEM and ODM service for Spring loaded pogo pin, pogo pin connector, magnetic connector, and magnetic charger cable.

RQB: Yes, our products meet CE and RoHs, we have been having a long-term partnership with some of global renowned electronics brands such as Dyson, Fitbit, etc

RQB: Yes, we accept sample and small order. We can send you our existing samples for you to make a test, also can customize samples for your project. Except that we can accept small order to support your business.

RQB: All of our products are 100% tested after production completed by our quality department. And we have 400 expereinced workers and advanced machines to guarantee lead time.

RQB: Yes, we are welcome you to visit our factory at your convenience, and we would like to sign NDA with you to protect your copyright and commercial benefits.