Products

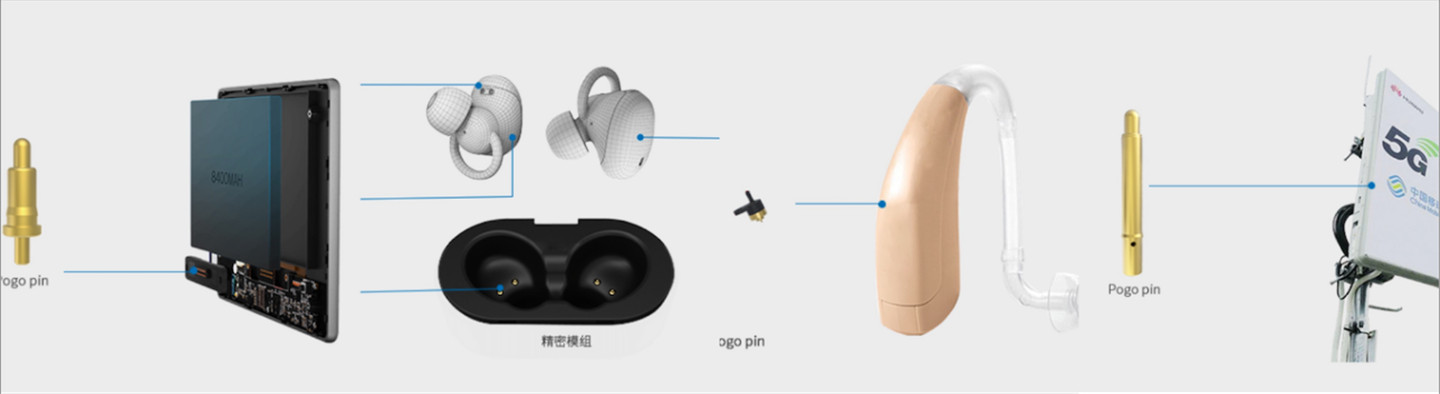

Double head Waterproof Spring Loaded Pogo Pin for Bluetooth Headphone

Specification

|

Material |

Plunger/barrel: Brass Spring: Stainless steel |

|

Electroplating |

Plunger: 1 micro-inch minimum Au over 50-120 micro-inch nickel Barrel: 1 micro-inch minimum Au over 50-120 micro-inch nickel |

|

Electrical specification |

Contact electrical resistor: 100 mOhm Max. Rated voltage: 12V DC Max Rated current: 1.0A |

|

Mechanical performance |

Life: 10,000 cycle min. |

|

Material |

Plunger/barrel: Brass Spring: Stainless steel |

|

Electroplating |

Plunger: 3 micro-inch minimum Au over 50-120 micro-inch nickel Barrel: 3 micro-inch minimum Au over 50-120 micro-inch nickel |

|

Electrical specification |

Contact electrical resistor: 100 mOhm Max. Rated voltage: 12V DC Max Rated current: 1.0A |

|

Mechanical performance |

Life: 10,000 cycle min. |

Application:

Intelligent wearable devices: Smart watches, smart wristbands, locator devices, Bluetooth headphones, smart wristbands, smart shoes, smart glasses, smart backpacks, etc.

Smart home, smart appliances, air purifiers, automatic controllers, etc.

Medical equipment, wireless charging equipment, data communication equipment, telecommunications equipment, automation and industrial equipment, etc;

3C consumer electronics, laptops, tablets, PDAs, handheld data terminals, etc.

Aviation, aerospace, military communication, military electronics, automobiles, vehicle navigation, testing fixtures, testing equipment, etc

FAQs

Pogo needles can be protected from damage by using protective caps, caps or shields and minimizing exposure to harsh environmental conditions.

Both spring-loaded contacts and pogo pins are spring-loaded connectors, but pogo pins are designed for high-reliability electrical connections in demanding applications.

Yes, pogo pins can be used for high frequency applications, but their performance may be affected by factors such as the length of the pin and the quality of the mating surface.

Yes, pogo pins can be used for high voltage applications, but their performance may be affected by factors such as pin size and material, and the contact resistance of the connections.

Yes, pogo pins can be used in harsh environments, but their performance may be affected by factors such as temperature, humidity, and dust.