Products

SMT/SMD Pogo Pin Keyboard

Specification

|

Material |

Plunger: Brass Barrel: SUS316F Spring: Stainless steel |

|

Electroplating |

Plunger: 5 micro-inch minimum Au over 50-120 micro-inch nickel Barrel: 50-100 micro-inch minimum Cu over 100-150 micro-inch nickel Spring: 1 micro-inch minimum Au over 30-50 micro-inch nickel |

|

Electrical specification |

Contact electrical resistor: 100 mOhm Max. Rated voltage: 12V DC Max Rated current: 1.0A |

|

Mechanical performance |

Life: 10,000 cycle min. |

About Us

Remark: Considering the difference between test spot and actual work spot, the impedance test condition defined by Top-Link is based on the whole working stroke. This is what we generally said dynamic impedance testing, it differs from the static test condition of ELA-364923, the durability test standard is also based on this test condition.

The main customers are Honeywell, Samsung, SIEMENS AG, ZTE, 360, QCY, HAYLOU, Shanghai Laimu, Luxshare Group, Aoni Electronics, Ampheno Group and other well-known enterprises.

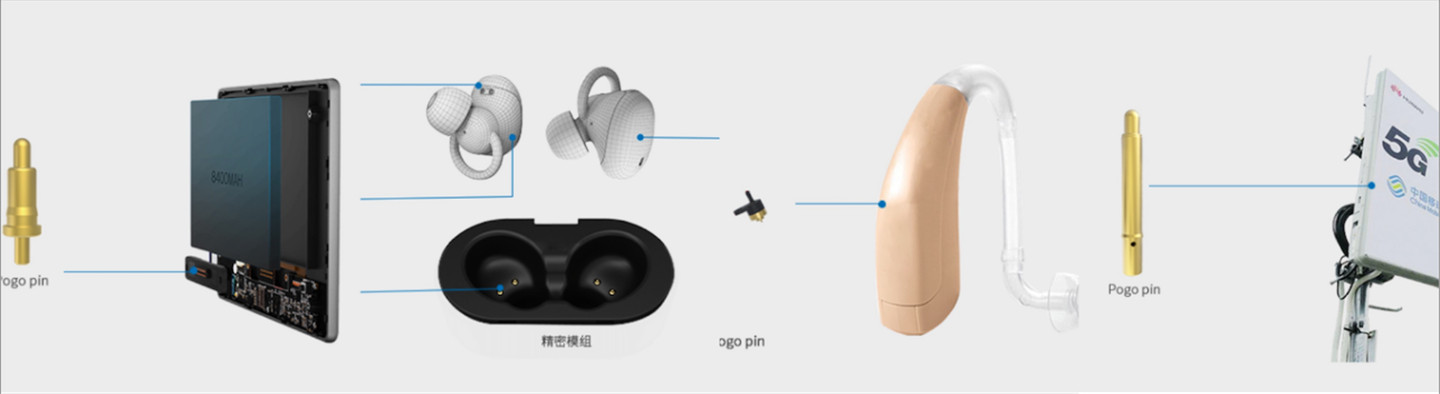

PRODUCTS AREA

Smart wearable products (wristbands, watches), mobile phones (mobile antenna), digital cameras, laptops, Bluetooth headsets, learning machines, games products, handheld game consoles, GPS satellite navigation, aerospace electronics, medical equipment, military communications, toys, portable electronic products.

Since the establishment of Our company, our spirit of "excellent quality, intimate service" concept, "customer-centric, create more value for customers" core values, these help us win the majority of customers.

FAQs

RQB: Yes, we are the experienced manufacturer in this industry, which can provide OEM and ODM service for Spring loaded pogo pin, pogo pin connector, magnetic connector, and magnetic charger cable.

RQB: Yes, our products meet CE and RoHs, we have been having a long-term partnership with some of global renowned electronics brands such as Dyson, Fitbit, etc

RQB: Yes, we accept sample and small order. We can send you our existing samples for you to make a test, also can customize samples for your project. Except that we can accept small order to support your business.

RQB: All of our products are 100% tested after production completed by our quality department. And we have 400 expereinced workers and advanced machines to guarantee lead time.

In some cases, a pogo pin can be repaired by replacing the spring or contact material, but in most cases it is more cost-effective to replace the entire pin.